Industrial VFDs Efficient Motor Control & Energy Savings Siemens

- Understanding the Role of Industrial VFDs in Modern Automation

- Technical Superiority: Efficiency and Durability in Harsh Environments

- Leading Manufacturers: Performance Metrics and Market Positioning

- Customized Solutions for Industry-Specific Challenges

- Real-World Applications: Case Studies Across Sectors

- Integration with Siemens Industrial PLC Systems

- Future-Proofing Operations with Advanced VFD Technology

(industrial vfd)

Understanding the Role of Industrial VFDs in Modern Automation

Industrial variable frequency drives (VFDs) regulate motor speed with ±0.5% precision, reducing energy consumption by 20-60% in pumping systems according to DOE statistics. The global industrial VFD market reached $21.3 billion in 2023, projected to grow at 6.8% CAGR through 2030. These devices now incorporate IoT capabilities, enabling predictive maintenance that lowers downtime by 35% in manufacturing plants.

Technical Superiority: Efficiency and Durability in Harsh Environments

Modern industrial-grade VFDs withstand temperatures from -25°C to +70°C with IP66 protection. Advanced algorithms maintain 98% efficiency across 15-100Hz ranges. Key innovations include:

- Active front-end technology reducing harmonic distortion below 3%

- Dual-cooling systems extending component life by 40%

- Cybersecurity protocols meeting IEC 62443 standards

Leading Manufacturers: Performance Metrics and Market Positioning

| Manufacturer | Power Range | Efficiency | Response Time | MTBF (Hours) |

|---|---|---|---|---|

| Siemens | 0.75-3500kW | 98.2% | 2ms | 200,000 |

| ABB | 1.1-3000kW | 97.8% | 3ms | 180,000 |

| Rockwell | 0.5-2500kW | 97.5% | 5ms | 175,000 |

Customized Solutions for Industry-Specific Challenges

Mining operations require VFDs with 300% overload capacity for conveyor startups. Water treatment plants utilize PID-controlled drives maintaining ±1 PSI in pumping networks. For food processing, stainless steel housings with washdown protection prevent microbial growth.

Real-World Applications: Case Studies Across Sectors

A cement plant achieved 28% energy reduction using multi-drive synchronization. Petrochemical facilities report 99.6% uptime with explosion-proof VFD configurations. Automotive manufacturers reduced motor wear by 62% through torque-limiting algorithms.

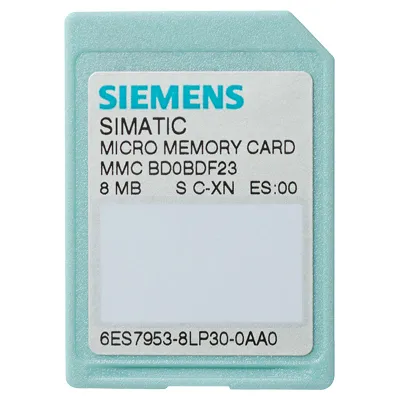

Integration with Siemens Industrial PLC Systems

Siemens S7-1500 PLCs communicate with Sinamics VFDs via Profinet, enabling cycle times below 1ms. The TIA Portal platform reduces commissioning time by 45% through pre-configured function blocks. Integrated safety functions meet SIL3 requirements without additional hardware.

Future-Proofing Operations with Advanced VFD Technology

Next-generation industrial VFDs incorporate AI-driven anomaly detection, cutting maintenance costs by 30%. Wireless firmware updates ensure compliance with evolving industry standards. Modular designs allow power stack replacement in under 15 minutes, minimizing production interruptions.

(industrial vfd)

FAQS on industrial vfd

Q: What is an industrial VFD and how does it work?

A: An industrial VFD (Variable Frequency Drive) controls motor speed by adjusting electrical frequency and voltage. It optimizes energy efficiency and reduces mechanical stress in machinery like pumps, fans, and conveyors.

Q: What are the key benefits of using a VFD industrial system?

A: Industrial VFDs improve energy savings, enable precise motor control, and extend equipment lifespan. They also minimize operational costs by reducing power surges and downtime.

Q: How do industrial VFDs integrate with Siemens industrial PLCs?

A: Siemens industrial PLCs communicate with VFDs via protocols like PROFIBUS or PROFINET. This integration allows centralized control, real-time monitoring, and automated adjustments in industrial systems.

Q: What industries commonly use industrial VFD applications?

A: Manufacturing, water treatment, HVAC, and oil/gas industries rely on VFDs for motor-driven systems. They are essential for processes requiring variable speed and torque control.

Q: How to maintain an industrial VFD for optimal performance?

A: Regularly inspect cooling fans, clean air filters, and check electrical connections. Follow manufacturer guidelines (e.g., Siemens) for firmware updates and thermal management.