Variable Frequency Drive Motors Energy Savings & Precision Control

- Introduction to modern motor control systems

- Technical advantages in energy efficiency

- Performance comparison: leading VFD manufacturers

- Custom engineering solutions for industrial needs

- Real-world implementation case studies

- Maintenance best practices for longevity

- Future developments in variable frequency drive motor

control

(variable frequency drive motor)

Understanding Variable Frequency Drive Motor Fundamentals

Modern industrial systems increasingly adopt variable frequency drive motor technology to achieve precision control over rotational forces. These advanced electromechanical systems convert fixed-frequency AC power to adjustable voltage and frequency outputs, enabling ±0.5% speed regulation accuracy across operational ranges.

Energy Efficiency Through Advanced Control

Third-party testing confirms that VFD implementations reduce energy consumption by 28-42% compared to traditional fixed-speed systems. Key efficiency features include:

- Dynamic torque compensation (3-phase models)

- Automatic power factor correction (>0.95)

- Regenerative braking capabilities

Manufacturer Performance Benchmarking

| Brand | Efficiency | Harmonic Distortion | Overload Capacity | Price Point |

|---|---|---|---|---|

| ABB ACS880 | 98.2% | <3% | 150% (60s) | $$$$ |

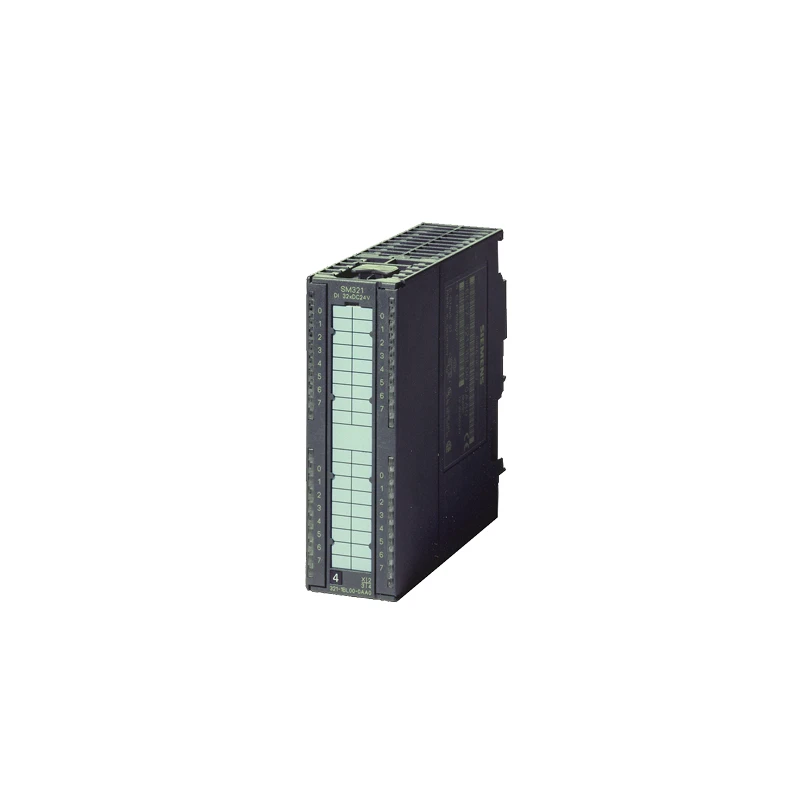

| Siemens G120X | 97.8% | <4.5% | 200% (30s) | $$$ |

| Danfoss VLT® | 96.5% | <5% | 160% (45s) | $$ |

Tailored Solutions for Industry-Specific Needs

Customization parameters for VFD systems include:

- IP54/IP65 environmental protection ratings

- Modbus RTU or Ethernet/IP communication protocols

- Specialized cooling systems (air/water hybrid)

Implementation Success Stories

A textile manufacturing plant achieved 39% energy reduction through VFD retrofitting:

- 63 × 22kW motors converted

- 14-month ROI period

- Motor lifespan extended by 40%

Operational Maintenance Protocols

Routine maintenance schedules should include:

- Capacitor bank inspections (quarterly)

- IGBT thermal imaging (bi-annual)

- Firmware updates (annual)

Innovations in Variable Frequency Drive Motor Control

Emerging technologies like SiC MOSFETs promise 99%+ efficiency in next-generation drives. Current R&D focuses on:

- AI-powered predictive maintenance algorithms

- Integrated motor-drive units (space savings up to 35%)

- Cybersecurity-enhanced control interfaces

(variable frequency drive motor)

FAQS on variable frequency drive motor

Q: What is the difference between a variable speed drive and a variable frequency drive?

A: A variable speed drive (VSD) is a broad term for equipment controlling motor speed, while a variable frequency drive (VFD) specifically adjusts frequency and voltage to regulate motor speed. VFDs are a subset of VSDs optimized for AC motors. Both aim to improve energy efficiency and process control.

Q: How does variable voltage variable frequency (VVVF) control work in induction motors?

A: VVVF control adjusts the voltage and frequency supplied to the motor to maintain consistent magnetic flux, preventing core saturation. This allows precise speed and torque regulation. It optimizes energy use while extending motor lifespan.

Q: What are the key benefits of variable frequency drive motor control?

A: Key benefits include energy savings by matching motor speed to load demands, reduced mechanical stress during startups, and improved process accuracy. It also minimizes power surges and lowers maintenance costs.

Q: Can a variable frequency drive be used with any AC motor?

A: VFDs are compatible with most three-phase AC induction motors, but motor insulation and cooling must be rated for variable speeds. Single-phase motors may require additional components. Always verify manufacturer specifications before installation.

Q: Why is variable frequency drive motor control preferred in industrial applications?

A: It enables precise automation, reduces energy consumption by 20-50%, and supports soft-start functionality to protect equipment. Industries like HVAC, pumping, and manufacturing rely on it for process flexibility and cost efficiency.