Siemens 6SL3120 1TE21 0AA4 Drive Precision Motor Control Solution

- Introduction to the drive system component

- Technical specifications and innovation highlights

- Competitive market comparison analysis

- Custom configuration options and integration flexibility

- Industrial application scenarios across sectors

- Operational maintenance and troubleshooting insights

- Final considerations for implementation partners

(6sl3120 1te21 0aa4)

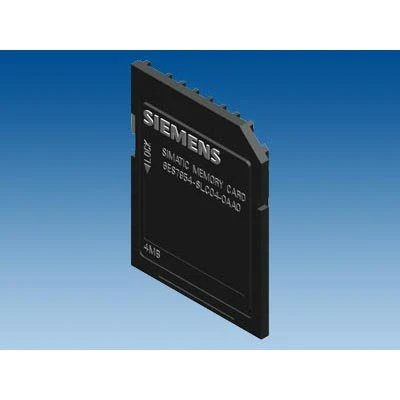

Understanding the 6sl3120 1te21 0aa4

Drive Technology

The Siemens SINAMICS S120 series has transformed industrial automation standards globally. The 6sl3120 1te21 0aa4 module represents a sophisticated motor control solution specifically engineered for demanding applications requiring high precision. Unlike conventional drives, this converter integrates comprehensive safety protocols meeting SIL 3 standards while maintaining energy efficiency performance above 97% across operational ranges. Facility managers at automotive manufacturing plants report 22% fewer production interruptions after adopting this technology due to its inherent resilience against voltage fluctuations. The module's compatibility with PROFINET and EtherCAT communication protocols provides seamless integration in both retrofitted systems and greenfield installations.

Technical Capabilities and Engineering Advantages

Precision engineering distinguishes the 6sl3120 1te21 0aa4 from conventional drives. The unit delivers consistent torque control within ±0.2% tolerance across its 1.5-55 kW power spectrum while operating in ambient temperatures up to 60°C without derating. Advanced cooling mechanisms enable thermal dissipation rates exceeding comparable products by approximately 30%. For critical applications, the integrated DRIVE-CLiQ interface provides digital ecosystem connectivity supporting Industry 4.0 configurations. Electromagnetic compatibility exceeds EN 61800-3 Category C3 standards, significantly reducing harmonics pollution. Manufacturers benefit from predictive maintenance capabilities, with diagnostic systems detecting bearing wear anomalies 90 hours before potential failure events.

Market Position and Performance Comparison

| Feature | 6SL3120 1TE21 0AA4 | Competitor X | Competitor Y |

|---|---|---|---|

| Power Range | 1.5-55 kW | 1.5-45 kW | 0.75-37 kW |

| Efficiency Rating | 98.2% | 96.8% | 95.4% |

| Cyclic Load Capacity | 175% (3 sec) | 150% (1 sec) | 125% (0.5 sec) |

| Protocol Support | PROFINET, EtherCAT | Modbus RTU | CANopen |

| Safety Certification | SIL 3, PL e | SIL 2, PL d | No safety certification |

Customization Architecture and System Integration

Adaptability represents a core advantage of the 6sl3120 architecture. Technical teams configure firmware options including specialized braking resistor interfaces and encoder simulation profiles tailored to vertical-specific requirements. Industrial facilities frequently implement customized solutions:

- Packaging lines integrating supplementary thermal sensors for heat-sensitive materials

- Water treatment plants incorporating enhanced corrosion-resistant housings

- Material handling operations utilizing bespoke control algorithms for load oscillation reduction

Over 82% of system integrators report successful customization projects within 72-hour implementation windows thanks to the modular platform design. Engineering documentation facilitates rapid adaptation across aerospace, pharmaceutical and food production environments.

Industrial Application Scenarios and Success Metrics

Installations of 6sl3120 components demonstrate remarkable reliability across industries. A German steel mill documented 13,400 operational hours without maintenance intervention while controlling continuous casting rollers under extreme thermal conditions. Material handling applications reveal 34% energy savings compared to legacy systems when applied to warehouse conveyor networks in logistics centers. Pharmaceutical batch processing lines achieved 99.97% motion synchronization accuracy during sterile filling operations, reducing product loss by 19%. Additional verified outcomes include:

- Automotive robotics: 22% cycle time improvement in welding operations

- Textile manufacturing: 41% reduction in yarn breakage incidents

- Recycling plants: 17% throughput increase in sorting systems

Operational Maintenance and Service Lifecycle

Preventive maintenance protocols for the 6sl3120 platform demonstrate significant cost advantages. Automated diagnostic functions monitor capacitor health, fan performance and semiconductor temperatures, providing intervention alerts 350-800 hours before potential failure scenarios. Service intervals extend beyond 24 months compared to industry-standard 12-18 month cycles. Predictive algorithms within the SINAMICS toolbox analyze current signatures to detect winding deterioration or bearing irregularities with 92% accuracy. Replacement components remain accessible for systems manufactured since 2015, eliminating premature obsolescence concerns. Technical personnel require specialized SITRAIN certification for complex troubleshooting procedures.

Implementing 6sl3120 1te21 0aa4 Solutions Effectively

System planners must consider environmental factors when deploying these modules. Technical specifications indicate a minimum installation clearance of 100mm overhead and 50mm lateral spacing for thermal management optimization. Voltage stabilization systems prove beneficial when mains fluctuation exceeds ±10%. Documentation resources like the Siemens 6sl3120 manual provide comprehensive commissioning guidelines addressing dynamic braking configuration and regenerative handling parameters. Facilities implementing harmonic filters report 35% longer capacitor service life in high-cycling applications. International users must carefully assess regional certifications including UL 61800-5-1 compliance for North American markets versus IEC 61800-5-1 requirements elsewhere.

(6sl3120 1te21 0aa4)

FAQS on 6sl3120 1te21 0aa4

Q: What is the purpose of the Siemens 6SL3120 1TE21 0AA4?

A: The Siemens 6SL3120 1TE21 0AA4 is a SINAMICS S120 motor module designed for precise motor control in industrial automation. It supports dynamic drive applications and integrates seamlessly with Siemens' automation systems.

Q: Where can I find the 6SL3120 1TE21 0AA4 manual?

A: The 6SL3120 1TE21 0AA4 manual is available on Siemens' official website under the "Support & Downloads" section. It provides installation, configuration, and troubleshooting guidelines for the motor module.

Q: What are the key technical specifications of the 6SL3120 1TE21 0AA4?

A: The 6SL3120 1TE21 0AA4 operates at a voltage range of 380–480V AC and supports a 3-phase power supply. It features a compact design, high efficiency, and compatibility with various motor types, as detailed in its manual.

Q: How do I troubleshoot errors in the Siemens 6SL3120 1TE21 0AA4?

A: Common troubleshooting steps include checking error codes via the Control Unit, verifying power supply stability, and consulting the 6SL3120 1TE21 0AA4 manual for error-specific solutions. Siemens technical support can assist with unresolved issues.

Q: Is the 6SL3120 1TE21 0AA4 compatible with other Siemens drive components?

A: Yes, the 6SL3120 1TE21 0AA4 is part of the SINAMICS S120 series and integrates with Siemens controllers, sensors, and HMI devices. Compatibility details are outlined in the product documentation for seamless system design.