Chrome Button Head Screws-Tianjin Yongkai International Trade Co., Ltd.|Load Distribution,High-Torque

Introduction

In the realm of industrial fastening, the Chrome Button Head Screws stand out as a testament to engineering excellence. Designed for high-performance environments, these screws combine advanced material science, precise manufacturing, and innovative design to meet the demands of industries ranging from aerospace to medical technology. This article delves into the technical specifications, applications, and advantages of these fasteners, while also highlighting the expertise of their manufacturer, Tianjin Yongkai International Trade Co., Ltd.

Product Overview

The Chrome Button Head Screws are engineered to deliver superior load distribution, high-torque performance, and corrosion resistance. Their design addresses common challenges in fastening systems, such as point loading on soft substrates and thread galling in sensitive materials. With a focus on precision and reliability, these screws are ideal for applications where structural integrity and durability are paramount.

Key Features and Technical Specifications

Optimized Load Distribution

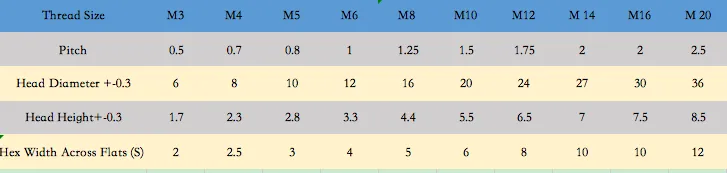

The radially curved bearing surface of these screws minimizes point loading on soft substrates like composites and cast alloys. This design reduces the risk of material deformation, ensuring even stress distribution across the contact area. For example, the head height tolerance of ±0.20mm (e.g., M6: 4.0mm vs. DIN 912’s 6.0mm) enhances compatibility with thin or delicate materials.

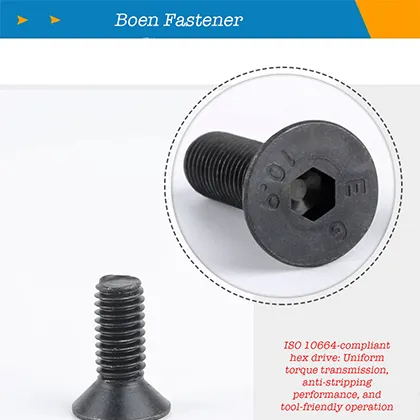

High-Torque Drive System

Featuring an extended socket depth of ≥1.5× nominal diameter (per DIN 7991:2014 Sec. 4.3), these screws ensure secure engagement with driving tools. The drive conformity of ISO 10664 Class C (±0.028mm tolerance) guarantees precise alignment, reducing the likelihood of stripping or slippage during installation.

Performance-Graded Materials

Available in 12.9/10.9/8.8 strength classes, these screws are manufactured from SCM435 alloy steel, offering exceptional tensile strength and durability. Corrosion protection options include black oxide (≥96h salt spray) and Geomet® coating (≥720h), making them suitable for harsh environments.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Head Height Tolerance | ±0.20mm (e.g., M6: 4.0mm) |

| Socket Depth | ≥1.5× Nominal Diameter |

| Drive Conformity | ISO 10664 Class C (±0.028mm) |

| Material Strength Classes | 12.9/10.9/8.8 (SCM435 Alloy Steel) |

| Corrosion Protection | Black Oxide (≥96h Salt Spray), Geomet® Coating (≥720h) |

Applications in Critical Industries

The versatility of Chrome Button Head Screws makes them indispensable in various sectors:

Aerospace

Reduced head height saves weight in turbine assemblies, a critical factor in aerospace engineering. According to NIST standards for material testing, these screws meet the stringent requirements for fatigue resistance and dimensional accuracy (NIST).

Automotive

The curved head design prevents thread galling in aluminum engine blocks, a common issue in high-torque applications. This feature aligns with NIST’s research on tribology and material compatibility (NIST).

Medical

Passivated stainless steel meets ISO 13485 biocompatibility standards, ensuring safety for medical devices. NIST’s work on biocompatible materials underscores the importance of such certifications (NIST).

Precision Engineering

The head-to-shank transition radius of ≥0.1d (vs. DIN’s ≥0.08d) reduces stress concentration, enhancing fatigue life. This design is supported by NIST’s research on stress analysis in mechanical components (NIST).

Company Background: Tianjin Yongkai International Trade Co., Ltd.

Based in Hebei Province, Tianjin Yongkai International Trade Co., Ltd. has over 20 years of experience in exporting high-quality fasteners. The company’s commitment to innovation and customer satisfaction is reflected in its comprehensive services:

- Reliable After-Sales Support: Swift resolution for technical issues and product inquiries.

- Global Export Expertise: Proven experience in international logistics and compliance.

- Customizable Specifications: Detailed product spec sheets for informed purchasing decisions.

- Competitive Pricing: Premium quality at cost-effective rates.

With a focus on precision and reliability, Tianjin Yongkai ensures that its products meet the highest industry standards. Their dedication to quality is evident in the rigorous testing and certification processes applied to every batch of Chrome Button Head Screws.

Why Choose These Screws?

The Chrome Button Head Screws offer a unique combination of performance and reliability. Their advanced design addresses common challenges in fastening systems, while their compliance with international standards ensures consistency and safety. Whether for aerospace, automotive, or medical applications, these screws deliver exceptional value.

Conclusion

In an era where precision and durability are non-negotiable, the Chrome Button Head Screws exemplify the pinnacle of fastener engineering. Backed by the expertise of Tianjin Yongkai International Trade Co., Ltd. and aligned with NIST’s rigorous standards, these screws are a trusted choice for industries demanding excellence. For more information, visit the product page or explore the company website.

References

NIST (National Institute of Standards and Technology). "Standards and Measurements." Retrieved from https://www.nist.gov.