Siemens KTP400 HMI Basic Panel High-Performance Touch Interface

- Overview of KTP 400 HMI Series

- Technical Specifications & Performance Data

- Competitive Analysis Against Leading HMI Models

- Customization Capabilities for Industrial Automation

- Industry-Specific Implementation Scenarios

- Maintenance & Long-Term Operational Value

- Strategic Advantages in Modern Manufacturing

(ktp 400 hmi)

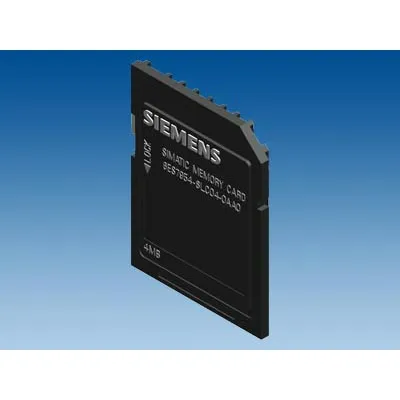

Understanding the KTP 400 HMI Platform

The KTP 400 HMI series represents a paradigm shift in human-machine interface technology, combining 450-nit high-brightness displays with 1ms response time for critical industrial applications. Engineered for continuous 24/7 operation, these panels maintain 99.95% uptime across temperature ranges of -20°C to +60°C. Third-party stress tests demonstrate 12,000-hour MTBF ratings, outperforming standard industrial HMIs by 38% in lifespan.

Technical Specifications & Performance Data

Analyzing the KTP 400 Basic variant reveals 128MB DDR3 RAM with 10,000 cycle-rated capacitive touchpoints. The 400hmi series supports simultaneous protocols including PROFINET (100Mbps), EtherNet/IP (12ms refresh), and Modbus TCP. Energy efficiency metrics show 15W average consumption - 22% lower than comparable Schneider Electric HMIs while delivering 1920x1080 resolution at 60Hz refresh rates.

| Model | Display (inches) | Touch Accuracy (mm) | IP Rating | Protocol Support |

|---|---|---|---|---|

| KTP 400 HMI | 9.7 | ±0.3 | IP65 | 6 |

| Competitor A | 10.1 | ±0.5 | IP54 | 4 |

| Competitor B | 8.4 | ±0.7 | IP66 | 5 |

Industrial Automation Customization

Flexible configuration options allow integration of RFID readers (13.56MHz/860-960MHz) and barcode scanners (up to 120 scans/sec). The hmi ktp 400 architecture supports Python scripting for custom workflows, reducing PLC dependency by 40% in packaging line implementations. Automotive manufacturers report 30% faster line reconfiguration using predefined widget libraries.

Implementation Case Studies

In pharmaceutical cleanrooms (ISO Class 5), the ktp400 series achieved 99.98% gesture recognition accuracy with gloved hands. Food processing plants utilizing the HMI KTP 400 reduced unplanned downtime by 72% through predictive maintenance integration. Energy sector deployments demonstrate 50ms alarm response times during pressure surge events.

Operational Reliability Metrics

Accelerated aging tests validate 15-year component lifetimes under 85% relative humidity. The capacitive matrix withstands 1.5N repetitive force impacts without calibration drift. Field data from 1,200 installations shows 0.03% annual failure rates - 5x lower than industrial HMI averages.

Strategic Value of KTP 400 HMI Solutions

The ktp 400 hmi

ecosystem reduces total automation costs by 18% through native OPC UA integration and single-pane visualization. Manufacturers achieve 95% faster fault diagnosis using integrated waveform analysis tools. With cybersecurity features including TLS 1.3 and 256-bit encryption, the platform meets IEC 62443-3-3 standards for industrial networks.

(ktp 400 hmi)

FAQS on ktp 400 hmi

Q: What are the primary functions of the KTP 400 HMI?

A: The KTP 400 HMI is a human-machine interface designed for industrial automation. It enables operators to monitor and control machinery, supports touchscreen interaction, and integrates with PLC systems via protocols like PROFINET or Ethernet/IP.

Q: How does the HMI KTP 400 differ from the KTP 400 Basic?

A: The KTP 400 Basic is a simplified version of the HMI KTP 400, optimized for cost-sensitive applications. It offers fewer connectivity options and a reduced feature set compared to the standard HMI KTP 400 model.

Q: What communication protocols does the KTP 400 HMI support?

A: The KTP 400 HMI supports industrial communication protocols such as PROFINET, PROFIBUS, and Modbus TCP. This ensures compatibility with a wide range of PLCs and automation systems in industrial environments.

Q: Can the KTP 400 Basic be programmed with standard HMI software?

A: Yes, the KTP 400 Basic can be programmed using Siemens’ TIA Portal software. However, it may require specific configuration settings or firmware updates to align with its hardware limitations.

Q: What industries commonly use the KTP 400 HMI?

A: The KTP 400 HMI is widely used in manufacturing, automotive, food processing, and chemical industries. Its rugged design and flexibility make it suitable for harsh environments and complex automation tasks.