Precision and Power: Why SIEMENS S7 1500 Is Leading the Industrial Automation Revolution

In a world where industrial automation demands smarter, faster, and more reliable systems, the siemens s7 1500 stands out as a high-performance PLC platform engineered for precision control. Combining outstanding speed, diagnostic capability, and integration readiness, the s7 1500 is more than just a controller—it’s the heart of smart factories. From complex material handling systems to seamless PROFINET networking, the siemens s7 1500 is setting new benchmarks in performance and efficiency.

Eliminating Downtime: Common Faults and Solutions in SIEMENS S7 1500

Even the most robust systems can face operational faults—but what distinguishes the siemens s7 1500 is its ability to detect, diagnose, and resolve issues with minimal disruption. Built-in diagnostic buffers, advanced error reporting, and integrated system diagnostics allow users to immediately identify faults like power module failure, I/O communication loss, or CPU stop conditions.

A typical example is when a 6es7590 1ae80 0aa0 fails to transmit signals accurately due to a wiring fault. The system generates an error log that pinpoints the exact module and signal path, saving valuable time in troubleshooting. By referencing the CPU's integrated web server, engineers can perform diagnostics without needing separate software tools.

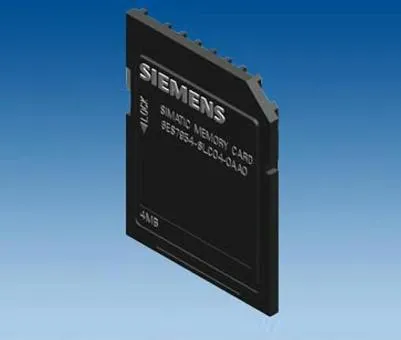

Overheating, corrupted memory cards, and inconsistent firmware can also trigger alerts. Fortunately, with the modular structure of the s7 1500, faulty components can be hot-swapped without taking the entire system offline. These capabilities minimize production downtime and reinforce the siemens s7 1500 as a cornerstone of industrial reliability.

Network Configuration and PROFINET Applications of S7 1500

Seamless connectivity is essential for industrial efficiency. The s7 1500 natively supports PROFINET, allowing it to function as an IO Controller, Device, or even both simultaneously, providing complete flexibility in network architecture.

When configuring a distributed control system, the s7 1500 communicates with HMIs, drives, and remote I/O over a single Ethernet backbone. Its built-in web diagnostics allow for real-time monitoring and commissioning without requiring third-party software, reducing the setup time for network administrators.

The 6es7590 1ae80 0aa0 backplane bus facilitates high-speed internal communication between modules, while external communication via PROFINET can integrate seamlessly with enterprise-level MES or SCADA systems. This makes the siemens s7 1500 ideal for factories pursuing digital transformation through Industry 4.0.

Moreover, network redundancy and data buffering capabilities mean even a temporary disconnection won’t disrupt operations—an essential feature in time-sensitive production lines. Whether it’s peer-to-peer communication or remote diagnostics, the siemens s7 1500 delivers flawless networking with minimal latency.

Enhancing Material Conveying Systems with SIEMENS S7 1500

One of the most prominent uses of the siemens s7 1500 lies in intelligent material conveying systems. These high-speed automation lines rely on precise timing, load balancing, and real-time feedback—all of which are perfectly handled by the s7 1500.

A recent installation in a logistics warehouse showcased the controller's power. By integrating multiple motor controllers, sensors, and barcode scanners via PROFINET, the s7 1500 monitored load positions and directed routing logic based on weight, destination, and priority.

The central controller, using a 6es7590 1ae80 0aa0 backbone for module expansion, handled complex conditional logic that adjusted conveyor speeds dynamically to prevent bottlenecks. When sensors detected excess load on a particular segment, the siemens s7 1500 rerouted incoming packages to less congested paths without halting operations.

In addition, the system was programmed to predict maintenance intervals based on sensor input, significantly reducing wear and tear and improving equipment lifespan. These smart adaptations not only increase throughput but also reduce labor costs and unplanned downtime.

How SIMATIC S7 1500 Price Reflects Its High-End Capabilities

Some may question the simatic s7 1500 price, but those familiar with its features know that it reflects a value far beyond initial cost. The return on investment comes quickly when factoring in its long-term reliability, advanced diagnostic tools, and dramatically reduced system downtime.

Unlike low-end PLCs that require constant attention and offer limited scalability, the siemens s7 1500 is engineered for complex operations that evolve over time. As production demands increase, additional I/O modules or expansion racks—like the 6es7590 1ae80 0aa0—can be easily added, turning a mid-sized control system into an industrial powerhouse.

Also, the simatic s7 1500 price includes access to an ecosystem of engineering tools, including TIA Portal, which simplifies configuration, programming, and maintenance in one integrated environment. Faster commissioning, easier troubleshooting, and longer equipment lifespan all contribute to cost savings that far outweigh the initial price.

For industries looking to balance premium performance with operational efficiency, the simatic s7 1500 price proves to be an investment in future-proof automation.

SIEMENS S7 1500 FAQs

What are the most common faults in the siemens s7 1500, and how are they fixed?

The most common faults include I/O communication errors, CPU stop conditions, and power module issues. The siemens s7 1500 includes built-in diagnostics that identify and isolate problems instantly, allowing for quick resolution and minimal downtime.

How does PROFINET integration benefit the s7 1500?

The s7 1500 uses PROFINET for seamless communication with distributed devices, supporting real-time data exchange, remote diagnostics, and plug-and-play installation. This makes it highly scalable for large automation networks.

Where is the siemens s7 1500 most commonly used?

It’s ideal for manufacturing, logistics, automotive, and process industries. Its advanced features and modularity make it suitable for both centralized control rooms and decentralized production environments.

What role does the 6es7590 1ae80 0aa0 play in the system?

The 6es7590 1ae80 0aa0 is a backplane bus unit used for expanding the module connectivity of the s7 1500, ensuring high-speed communication and signal integrity across multiple racks.

Is the simatic s7 1500 price worth it for small to mid-sized operations?

Absolutely. While the simatic s7 1500 price is higher than basic PLCs, its reliability, performance, and advanced diagnostics result in lower maintenance costs, faster commissioning, and greater ROI over time.