Optimal 5HP Motor VFDs Precision Control & Energy Efficiency

- Understanding the Role of VFDs in 5HP Motor Systems

- Technical Advantages of Modern 5HP Motor VFDs

- Performance Comparison: Top VFD Manufacturers

- Custom Solutions for Specific Operational Needs

- Real-World Applications Across Industries

- Installation and Maintenance Best Practices

- Optimizing ROI with the Right VFD for 5HP Motors

(vfd for 5hp motor)

Understanding the Role of VFDs in 5HP Motor Systems

Variable Frequency Drives (VFDs) for 5HP motors have become critical components in industrial automation, enabling precise speed control while reducing energy consumption by 25-40% compared to fixed-speed systems. A 5HP (3.7kW) motor typically requires a VFD rated for 7.5-10HP to handle startup surges, with input voltage compatibility being crucial for three-phase 208-480V systems.

Technical Advantages of Modern 5HP Motor VFDs

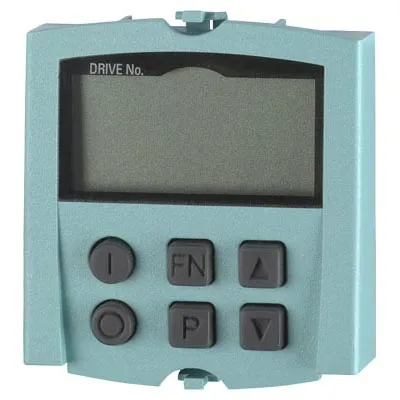

Contemporary VFDs offer dynamic torque control (±0.2% speed accuracy) and built-in PLC functionality. Advanced models feature:

- 95-98% energy conversion efficiency

- Multiple PID control loops

- RS-485/CANOpen communication protocols

- IP54-rated enclosures for harsh environments

Performance Comparison: Top VFD Manufacturers

| Brand | Rated Current | Input Voltage | Efficiency | Price Range | Key Advantage |

|---|---|---|---|---|---|

| ABB ACS550 | 12A | 380-480V | 97% | $850-$1,200 | Advanced harmonics suppression |

| Siemens G120C | 11A | 380-480V | 96.5% | $900-$1,300 | Integrated safety functions |

| Danfoss VLT | 13A | 208-240V | 95.8% | $780-$1,100 | Compact footprint |

Custom Solutions for Specific Operational Needs

Specialized configurations address unique requirements:

- Pump applications: Anti-cavitation algorithms

- Conveyor systems: Master-slave synchronization

- HVAC installations: Bypass circuit integration

Real-World Applications Across Industries

A food processing plant reduced energy costs by 32% after retrofitting 35×5HP motors with VFDs, achieving full ROI in 14 months. Similarly, a wastewater treatment facility extended motor lifespan by 40% through soft-start functionality.

Installation and Maintenance Best Practices

Proper implementation requires:

- EMC-compliant cabling (shielded 3+3 configuration)

- Thermal derating (10% capacity buffer)

- Quarterly filter replacement cycles

Optimizing ROI with the Right VFD for 5HP Motors

Selecting appropriate VFDs for 5HP motors requires balancing initial investment against lifecycle savings. Premium models typically demonstrate 18-24 month payback periods through energy savings and reduced maintenance. Always verify UL/CE certifications and manufacturer warranty terms (standard 3-year coverage with optional extensions).

(vfd for 5hp motor)

FAQS on vfd for 5hp motor

Q: How to choose a VFD for a 5hp motor?

A: Select a VFD rated for at least 5hp (3.7kW) with matching voltage and current specifications for your motor. Ensure it supports the motor's phase type (single or three-phase) and includes necessary protections like overload and short-circuit.

Q: Is a VFD for a 3-phase 5hp motor different from a single-phase model?

A: Yes. A VFD for a 3-phase 5hp motor requires three-phase input and output, while single-phase models are designed for single-phase power sources. Always verify the motor’s phase compatibility before purchasing.

Q: What size VFD do I need for a 5hp motor?

A: A 5hp motor typically requires a 5hp-rated VFD (≈4kW). However, size up by 20% (to 6hp) if the motor operates under heavy loads or frequent starts/stops to ensure durability and performance.

Q: Can I use a three-phase VFD for a 5hp motor with single-phase power?

A: Some three-phase VFDs accept single-phase input but derate their output capacity. Check the manufacturer’s specifications to confirm compatibility and adjust the VFD size to avoid underpowering the motor.

Q: What features are critical in a VFD for a 5hp motor?

A: Prioritize voltage/phase matching, overload protection, adjustable frequency range, and thermal management. For industrial use, opt for models with communication interfaces (e.g., Modbus) for system integration.