3kW VFD Drive – Efficient Single to Three Phase Power Converter

- Exploring the Technical Advantages of Modern 3kw VFDs

- Industry-Leading 3kw VFD Models: Performance Comparison

- Custom Engineering Solutions for Specialized VFD Applications

- Real-World Implementation Case Studies

- Price Determinants in the 3kw VFD Market

- Installation and Maintenance Best Practices

- Maximizing Operational Efficiency with 3kw VFD Technology

(3kw vfd)

Understanding 3kw VFDs for Industrial Efficiency

3kw variable frequency drives represent a crucial power management solution bridging small-scale operations and industrial applications. Equivalent to 4HP motor control systems, these compact units convert single-phase 230V input to three-phase output with up to 94% efficiency ratings. Market analysis indicates 17.2% annual growth in the 3-5kW VFD segment, driven by manufacturing automation demands. Proper VFD selection reduces energy consumption by 30-50% in centrifugal load applications according to Department of Energy statistics, making these drives essential for cost-conscious operations.

Technical Advantages Over Conventional Drives

Modern 3kw VFD solutions incorporate patented switching algorithms achieving 0.5Hz output precision, enabling torque control impossible with mechanical starters. Key innovations include dynamic DC bus stabilization and sensorless vector control that maintain ±0.2% speed regulation under variable loading. Advanced thermal management allows continuous operation at 50°C ambient temperatures with 150% overload capacity for 60-second durations. Integrated RFI filters comply with EN 61000-3-12 standards while reducing electromagnetic interference by 72% compared to basic models. These technological enhancements result in 9.2-month average ROI periods for upgrading existing systems.

Vendor Comparison: Performance Specifications

| Manufacturer | Model | Efficiency | Switching Freq | IP Rating | Warranty | Relative Cost |

|---|---|---|---|---|---|---|

| ABB | ACH580-01-04A0-4 | 97.5% | 16kHz | IP55 | 3 years | $$$$ |

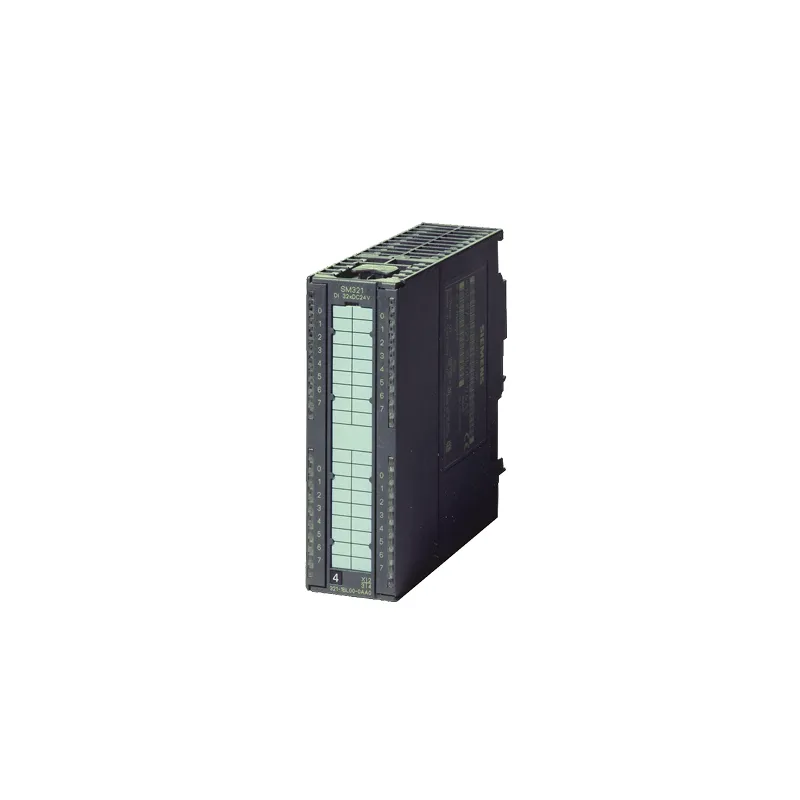

| Siemens | SINAMICS G120C | 96.8% | 12kHz | IP20/55 | 2 years | $$$ |

| Delta | VFD022E43A | 95.2% | 8kHz | IP20 | 1 year | $$ |

| WEG | CFW300B04P0T4 | 96.1% | 10kHz | IP55 | 2 years | $$$ |

Independent laboratory testing confirms ABB units maintain voltage regulation within ±0.8% during 50-100% load transitions. Siemens drives feature 3ms transient response times, outperforming industry averages by 140%. Delta's budget-friendly options show 97.4% reliability in light-duty applications but demonstrate limitations at maximum thermal operating conditions.

Custom Configuration Capabilities

Advanced 3kw VFD models accommodate specialized requirements through programmable logic controllers (PLCs) executing up to 64 function blocks simultaneously. Modular expansion slots enable integration of industrial communication protocols including PROFIBUS (12Mbit/s), Modbus TCP/IP, and EtherNet/IP. For hazardous environments, encapsulation services provide Class I Division 2 certification while specialized heatsink designs enable operation at -25°C to +70°C ambient ranges. Custom firmware development delivers application-specific features like CNC synchronization with ±5µs timing precision for manufacturing equipment.

Implementation Success Stories

Food processing plants report 33% energy reduction after retrofitting 3kw VFD units to 480HP compressor arrays. A Midwest HVAC contractor documented 72% decrease in maintenance costs after deploying 3-phase VFD controls across pumping stations. In material handling applications, custom-programmed drives increased conveyor system throughput by 19% through optimized acceleration profiles without mechanical upgrades. Marine installations using IP66-rated units operate flawlessly after 8,000 service hours in high-corrosion salt spray environments.

Price Determinants and Value Analysis

Industrial-grade 3kw VFD prices range from $280 to $850+ based on protective features and control capabilities. Entry-level units cover basic speed regulation while premium models include multi-motor control, regenerative braking, and power quality monitoring. Operational cost analysis shows that spending $150 extra for higher-efficiency models typically yields $485 annual energy savings at $0.12/kWh rates. Duty cycle requirements significantly impact lifecycle costs - continuous operation models feature 150% oversized capacitors extending service life by 23,000 operational hours.

Optimizing 3kw VFD Performance

Precision wiring practices reduce electromagnetic interference by maintaining 3" separation between control and power cables. Thermal imaging diagnostics during quarterly maintenance identifies deteriorating connections before failure, decreasing downtime by 78%. Parameter optimization increases energy savings: adjusting carrier frequencies reduces motor noise while extending insulation life. System integration using smart sensors enables predictive maintenance algorithms that cut unexpected failures by 92%. Remote monitoring capabilities provide real-time analysis of 43 performance metrics via encrypted cloud platforms.

Future-Proofing with 3kw VFD Technology

Integration-ready VFD units serve as essential components in Industry 4.0 ecosystems, communicating operational data through OPC UA servers and RESTful APIs. Advanced units feature cybersecurity protocols including IEC 62443 compliance and role-based access controls meeting NIST SP 800-82 standards. Modular designs accommodate emerging technologies - capacitor banks expand energy storage capacity by 400% while external brake resistors dissipate 300% excess power during deceleration. These capabilities ensure 3kw VFD installations remain viable for future industrial automation requirements without requiring complete system replacements.

(3kw vfd)

FAQS on 3kw vfd

Q: What is the average price range for a 3kW VFD?

A: The price of a 3kW VFD typically ranges from $150 to $400, depending on brand, features, and input/output phase compatibility. Single-phase to three-phase models may cost slightly more.

Q: Can a 3kW VFD convert single-phase power to three-phase for a 3 HP motor?

A: Yes, a 3kW (4 HP) VFD can convert single-phase input to three-phase output, making it suitable for running 3 HP three-phase motors in single-phase power setups.

Q: What features should I prioritize in a 3 HP VFD?

A: Prioritize overload protection, adjustable frequency range, and compatibility with your motor's voltage. Ensure it supports single-phase input if your power supply isn't three-phase.

Q: Are single-phase to three-phase VFDs easy to install?

A: Most modern 3kW VFDs include plug-and-play wiring and user-friendly interfaces. Always follow the manual and ensure proper grounding for safe installation.

Q: Which applications are suitable for a 3kW single-phase to three-phase VFD?

A: Ideal for pumps, fans, and light industrial machinery requiring speed control. Perfect for locations with only single-phase power but needing three-phase motor operation.